As a new charging device, blast furnace charging equipment is widely applied for charging raw material into a blast furnace for iron making. It gradually replaces bell top charging system.

Types of blast furnace charging equipment

All of the blast furnace charging equipment adopt modular standard unit overlaying structure, and the structure facilitates replacement and installation. Our blast furnace charging equipment has standard structure or compact structure. The structure can also be arranged according to users’ needs.

Blast Furnace Receiving Hopper

Receiving hopper is located at the top of the blast furnace and is used to store the materials transferred by conveyor belt.

Blast Furnace Burden Tank

When used together with the burden valve and seal valves, blast furnace burden tank could be used to store the materials transferred from receiving hopper.

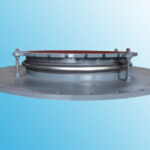

Metal Bellows Expansion Joint

Consist of two types called Top metal bellows expansion joint and Bottom metal bellows expansion joint

Blast Furnace Material Distributor

Blast furnace material distributor includes electric distributor and hydraulic distributor.

Furnace Burden Flow Regulating Valve

Furnace burden flow regulating valve regulates the flow of the charging materials in the blast furnace. The furnace burden flow regulating valve mainly controls the diamond-shaped hole of the valve plate.

Furnace Upper and Lower Sealing Valve

Furnace sealing valves serve to create a gas-tight chamber.

Blast Furnace Burden Valve

The baffle plates of blast furnace burden valve are ball shaped. Therefore, the valve is also named as ball shaped burden valve. It is composed of two ball shaped baffle plates who share the same center.

Blast Furnace Chute

Blast furnace chute is designed as a half cylinder structure, which could be used to convey materials to proper location according to the puddling requirements.

Established in 2004, Petro-Tec is a privately owned Pakistan-based company. Petro-Tec deals in sales and marketing in the oil, gas, and petrochemical sectors.